We’re always on the hunt for new and cool architecture trends and we’ve noticed that 3D printing has been making headlines for quite some time now. Considering that you can 3D print almost anything in the world, from skin grafts to guns, it’s safe to say that 3D printing is the future of printing.

For those who are unfamiliar with 3D printing, it is a process of making a physical object from a 3D model. Thin layer upon thin layer of material (usually concrete in construction) is laid down until it’s built up to the full object/structure. It’s very common in the healthcare industry but it’s making it’s way into other industries too, like architecture.

In terms of architecture, 3D printing comes with plenty of benefits and savings. It cuts out the fabricating step completely, which saves time, labour and transportation costs compared to traditional construction methods. However, the cost of 3D printing still far exceeds that of regular construction materials like brick and stone. Regardless, with 3D printing, architects can achieve a strong structure using less material than a normal structure which amps up the benefits of 3D printing by far.

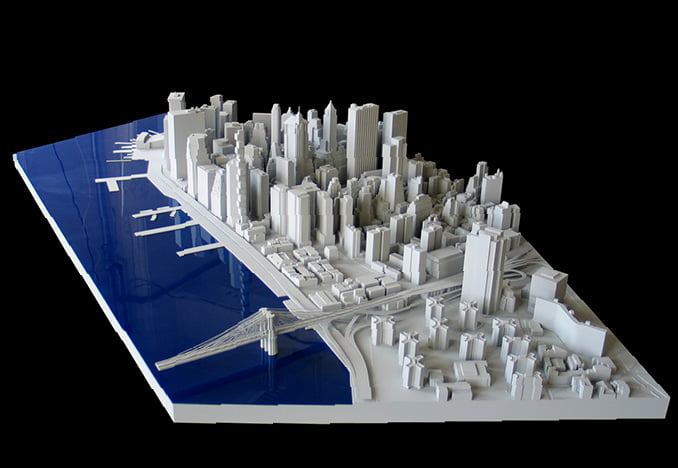

Last year saw the emergence of the 3D-printing craze, with architecture firms from all around the world racing to be the first to build a structure out of 3D printers. Many architecture firms use 3D printers to help make models because of its accuracy and efficiency.

As recent as a few months ago, British architect Adrian Priestman designed and installed the first 3D-printed components to be approved for use in construction. He developed a decorative sheath for a canopy on the roof of an office building in Central London. This was one of the first 3D-printed applications used in a building and it’s projected to stand for fifteen or twenty-years.

Last summer, California studio Smith|Allen completed the world’s first architectural structure using standard 3D printers, called Echoviren. The pavilion (10 x 10 x 8 foot) consists of 585 individually printed components produced on only seven printers made by Type A Machines. We’ve always wondered how long a project like this takes to print, and for Echoviren it took approximately 10,800 hours to print but four days to assemble.

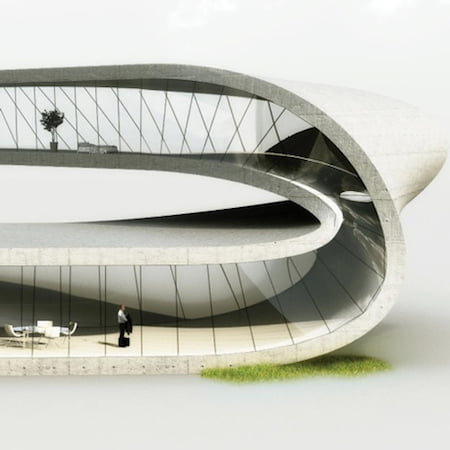

And this is all just the beginning. Dutch architecture studio Universe Architecture is planning to construct a house with a 3D printer for the first time using printers that produce mixtures of sand and a binding agent. It’s not just any simple building either, the house will resemble a Mobius strip! We’re excited to see where the trend takes us.

Who knows. Maybe we’ll use a 3D printer to make our next project!